Stage design often captivates with large and elaborate theater sculptures, but this is also associated with significant material usage and partially non-recyclable waste. In the research project GreTA, the Institute of Lightweight Engineering and Plastic Technology (ILK) at TU Dresden and the Theater Sculpture program at the Dresden Academy of Fine Arts (HfBK) jointly explore how theater sculptures can be produced and utilized in a more environmentally friendly manner through state-of-the-art technologies and sustainable materials.

Professor Ulrich Eißner from the Dresden Academy of Fine Arts emphasizes, "The HfBK Dresden, as one of the oldest European art academies, has always been a place where art technologies and craftsmanship have continuously evolved. We hold theater sculptors to this standard as well. Creating artistically high-quality, stable, lightweight, durable, and at the same time resourceefficient and sustainable theater sculptures is the major future theme in theater sculpture. Through our research in collaboration with ILK, we aim to become pioneers in this field throughout Europe.“

Professor Dr.-Ing. Niels Modler from ILK states, "Our scientific team brings extensive technological, organizational, and scientific analytical expertise to the collaboration. We also have profound experience in material testing techniques, lightweight construction, as well as design and industrial applications. However, the GreTA project also allows for the derivation of further research fields, which we will advance with cooperation partners from other areas such as architecture, construction, or design."

The research project GreTA (Generative Production of Recyclable Base Structures for Theater Sculpture from Nature-Based Materials) is funded by the SMWK with approximately €580,000 from September 2021 to the end of August 2024.

Minister of Science Sebastian Gemkow says, "Through our state funding, we support collaborations across disciplines and fields to promote innovation. In the GreTA project, two cooperation partners are working together, initially appearing to have distinct themes. Together, they are researching new and resource-efficient technologies and solutions that, ideally, can also be utilized for other applications. I wish the team from the Institute of Lightweight Engineering and Plastic Technology and the Dresden Academy of Fine Arts much success."

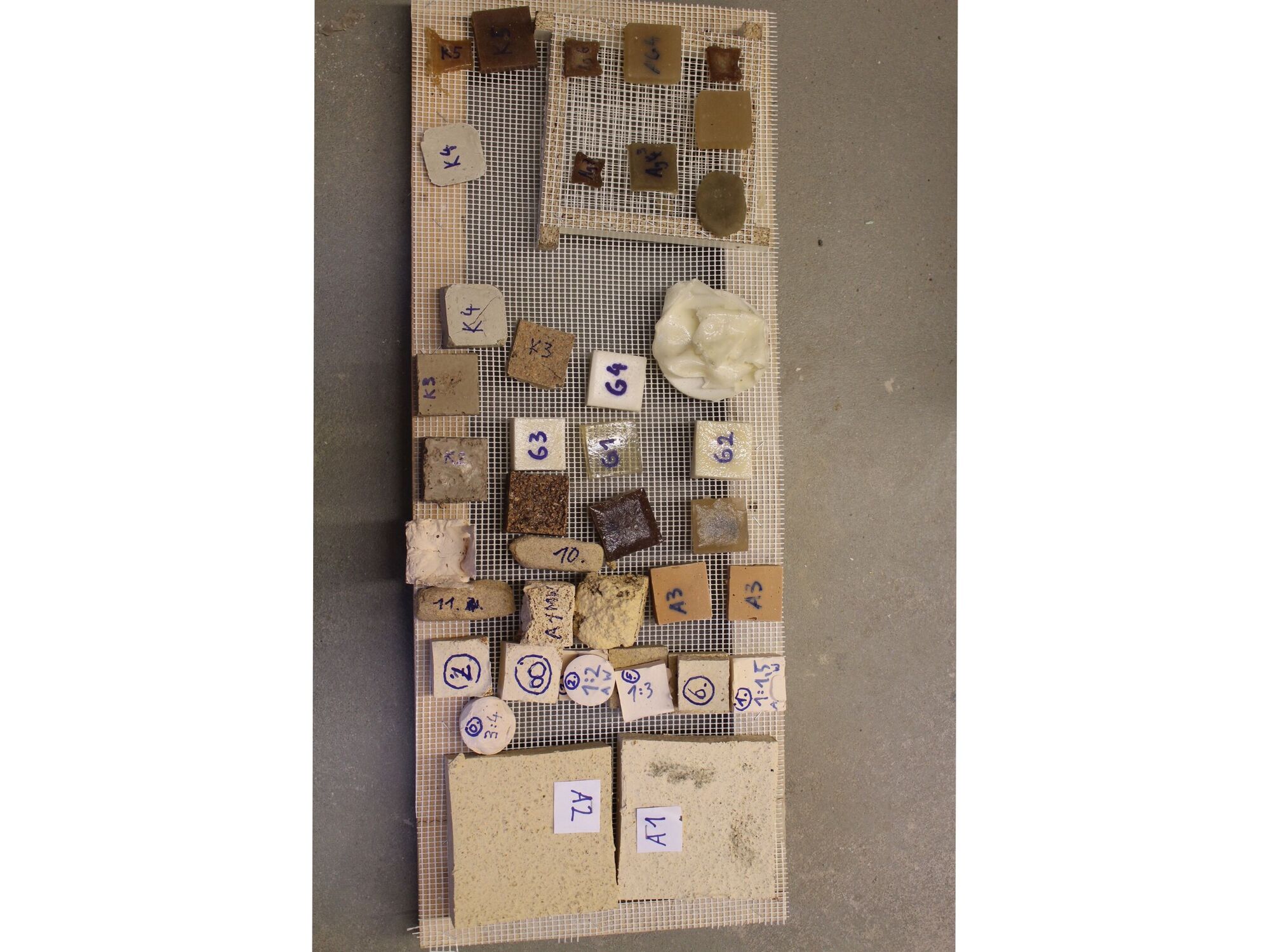

After extensive testing of various material combinations for large-scale 3D printing, we are getting closer to reliably reproducible results, and initial collaborations and applications are emerging. Using the large-scale 3D printer, we can build layer by layer parts ranging from 30 to 70 cm in height using our nature-based pastes. The results are pioneering due to their stability, minimal

shrinkage, and lightweight. Larger models can still be produced by assembling multiple segments. Furthermore, it is possible to grind faulty printouts or no longer needed models using our in-house "Pulverisette" and reintroduce them into the printing mixture by heating a new batch. If for any reason the material cannot be reintroduced into the cycle, it can be composted.

However, basic structures for larger models can be produced not only through 3D printing. We also utilize digital 3D data (created, for example, with a 3D scanner) to cut out the outlines of individual layers from corrugated cardboard. Stacking these layers is a cost-effective and efficient way to create larger volumes. Cardboard is a sustainable material due to its excellent recyclability.

By using a non-polymer-based adhesive such as casein or gelatin to fix the layers, environmentally safe structures can be created.

In addition to additive manufacturing processes for specific models, we have also put an extruder into operation. This device exerts extremely high pressure on plant-based raw materials (such as cornmeal), causing them to foam and extrude as a long strand through a nozzle. These watersoluble foams may provide an alternative to petroleum-based foams and could be used in

traditional processing methods through subtractive techniques. Looking ahead, there is still much work to be done in various areas to further optimize processes and materials. In addition to volume and adhesives, surface finishing materials will also be tested. How well can printed structures be protected against wind and weather, and which materials can be manually worked on and supplemented on the surface? There will certainly be a few surprises in the coming months. Stay tuned!